Our Process

We specialize in carbon fiber

Our carbon fiber manufacturing skillset sets up apart from all other consumer composites manufacturers. We encourage you to compare the quality, finish, and strength of our composite materials to other manufacturers, who typically buy their carbon in preformed sheets from industrial suppliers who focus on cost over quality.

Made in America

DFWcomposites was founded to allow everyone to experience the beauty and benefits of carbon fiber, a space age material, in their everyday lives. We manufacture our carbon products in house, right here in Dallas, Texas in our own facility. Since we process our carbon parts from raw material to finished product, we're able to offer an amazing variety of customization options to help make your purchase unique to your tastes. Doing all of our manufacturing in house means we can offer the highest levels of quality control and attention to detail, and we proudly embrace our Made in the USA label.

The Carbon

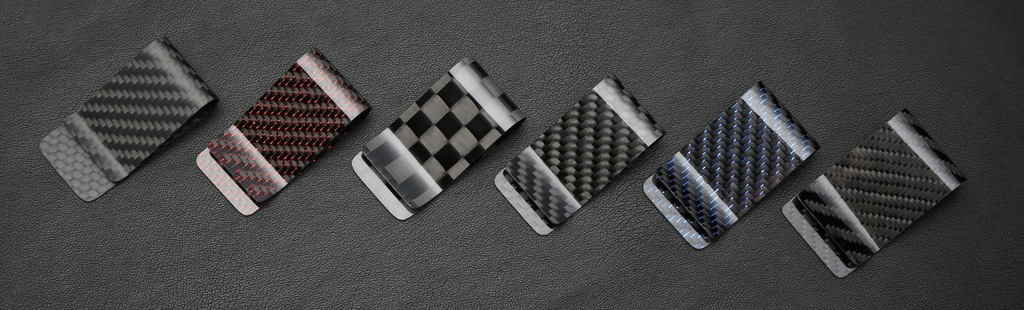

We've developed a proprietary forming process that creates high gloss, ultra durable carbon parts. This unique process allows us to offer a wide variety weave styles, and we believe this sets us apart from other manufacturers - while most buy their finished carbon stock from large manufacturers, we're able to make small runs of specialty weave styles (such as spread tow or metallic laced parts) that are some of the most unique and attractive looking carbon parts on the market. See the gallery below to find out what we mean.

Gallery